Inquiry Now

Through the "CUP to CUP" Regeneration Path : RPET is Becoming Another Great Choice

As an important basic material, plastics bring many conveniences and challenges to environmental governance. For more than 40 years, PET packaging has provided high sustainability, value and consumer appeal. So, is there a more environmentally friendly plastic material that can better meet commercial and economic needs?

In recent years, Coca-Cola, Nestle, Pepsi, Unilever and others have pledged to increase the use of RPET packaging in their businesses. RPET is emerging as an environmentally friendly new material.

First, let's clarify what PET is.

PET (polyethylene terephthalate) is a thermoplastic polymer that is lightweight, durable, safe, transparent, and has a high collection rate. It is often used as a packaging material for food and beverages due to its high transparency, cold resistance, food contact, and antimicrobial properties. When it was in the textile industry, it also had a famous brother called polyester fiber.

So what is RPET?

RPET is an abbreviation for recycled polyethylene terephthalate and refers to any PET material derived from recycled sources rather than raw, unprocessed petrochemical feedstocks.

RPET is an environmentally friendly polymer material. Products can also be divided into fiber grade RPET, bottle grade RPET and film grade RPET according to form and main use, and are used in food packaging, textile, clothing and other industries.

How does PET become RPET after recycling?

After PET is recycled, it consists of four consecutive stages:

- After collection, initially separate the bottle cap label and wash the entire bottle.

- Crushing, dust removal, further cleaning, sorting

- Mixing and formulation with additives

- Reactive compounding

Benefits of RPET:

Reduced environmental burden - PET cups take at least hundreds of years to fully decompose under natural conditions, placing a burden on the environment and the economy. Outside the recycling system, RPET regenerated by physical or chemical methods can reduce carbon dioxide emissions by 59% and energy consumption by 76%.

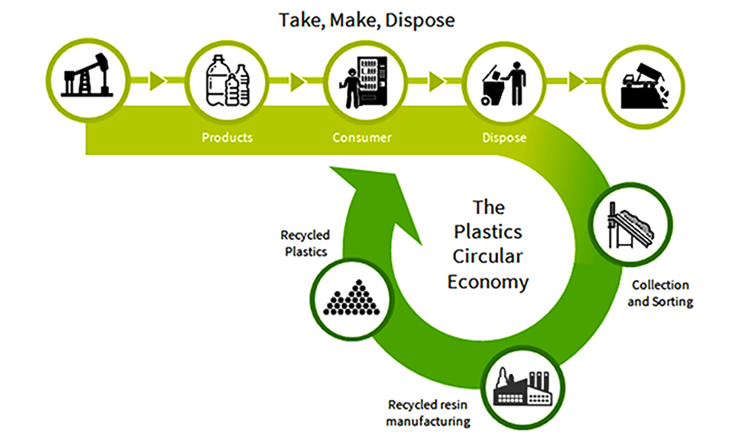

Promote circular economy - remanufacturing PET cups into food grade RPET, reducing the use of primary PET, thereby reducing the consumption of non-renewable resources such as oil, increasing the number of PET cycles, and forming a circular plastic economy.

Reduced cost input - Compared with the use of natural resources such as oil as raw materials, less water and energy are used at the same time, which greatly reduces the cost of raw materials; the final product will also be relatively light, and the transportation cost will also be reduced.

Excellent quality - RPET products also inherit the characteristics of PET products, which are light, durable, highly transparent and smooth, and can also be recycled.

In order to promote the production and utilization of RPET and accelerate the promotion of circular economy, many international brands around the world have taken corresponding measures or set relevant goals. JKAI is also actively applying RPET to production. Through the "CUP to CUP" regeneration path, JKAI will vigorously promote environmental protection and achieve green development goals!