Inquiry Now

Jkai's Strict and Comprehensive Quality Management Provide You Reliable PET Cup Solutions

Quality control is an important link for an enterprise to ensure product quality in the production process, which covers the whole process from raw materials to products. Jkai strictly carries out quality control management, aiming to ensure that our product —— PET direct drinking container can fully meet established quality standards before being delivered to consumers.

Adhering to the "quality one vote no" attitude, Jkai converts customers' needs for product quality, delivery time, cost, etc. into measurable product indicators, and implements and iterates in the whole process of daily production, effectively ensuring the reliability and consistency of products and meeting customers' needs in various commercial application scenarios.

A. High-standard factory and workshop environment supports production support

Safety Assessment, Environmental Assessment

At the beginning of the plant construction, Jkai had already completed the safety assessment and environmental impact assessment report, and the relevant safety conditions and production environment were assessed as compliant, laying a solid foundation for ensuring production hygiene and safety;

Class 100,000 GMP clean workshop

Locker rooms, clean corridors, moulding workshops, printing workshops and other test areas have all met the relevant requirements of the Class 100,000 GMP clean workshop in GB 50687 and GB 15979. Temperature and humidity, noise, suspended particles and other test items are also judged to be qualified according to GB / T 16292. All equipment and personnel also passed the sampling inspection.

Jkai's production workshop, administrative area and park have all established "6S" on-site management standards and systems from the six projects of "SEIRI, SEITON, SEISO, SEIKETSU, SHITSUKE and SECURITY", and regularly inspect and rectify to ensure the health and safety of the food-grade production environment and reduce risks at all times.

A. Strict quality management system and control process

QC team and testing equipment

JKai has an independent QC department and a variety of detection, experiment and measurement equipment. The professional quality team is equipped with a total of 8 QC personnel, covering every link to every professional technical test involving products, achieving high-quality products;

Professional technical certification

Jkai's products have been certified by ISO, BRC, BSCI, GRS, Halal certification, etc. At present, Jkai has applied for 11 utility model patents and 2 invention patents to improve product technical barriers and escort customers.

Control and testing in each link

On the basis of ISO and other authoritative management systems, Jkai has established its own strict quality control systems and control processes: from raw materials to finished products, each link and each process must strictly implement the first inspection, patrol inspection, warehousing inspection, and outbound inspection. Make sure that each parameter matches the standard and corrects before moving on to the next step of the process.

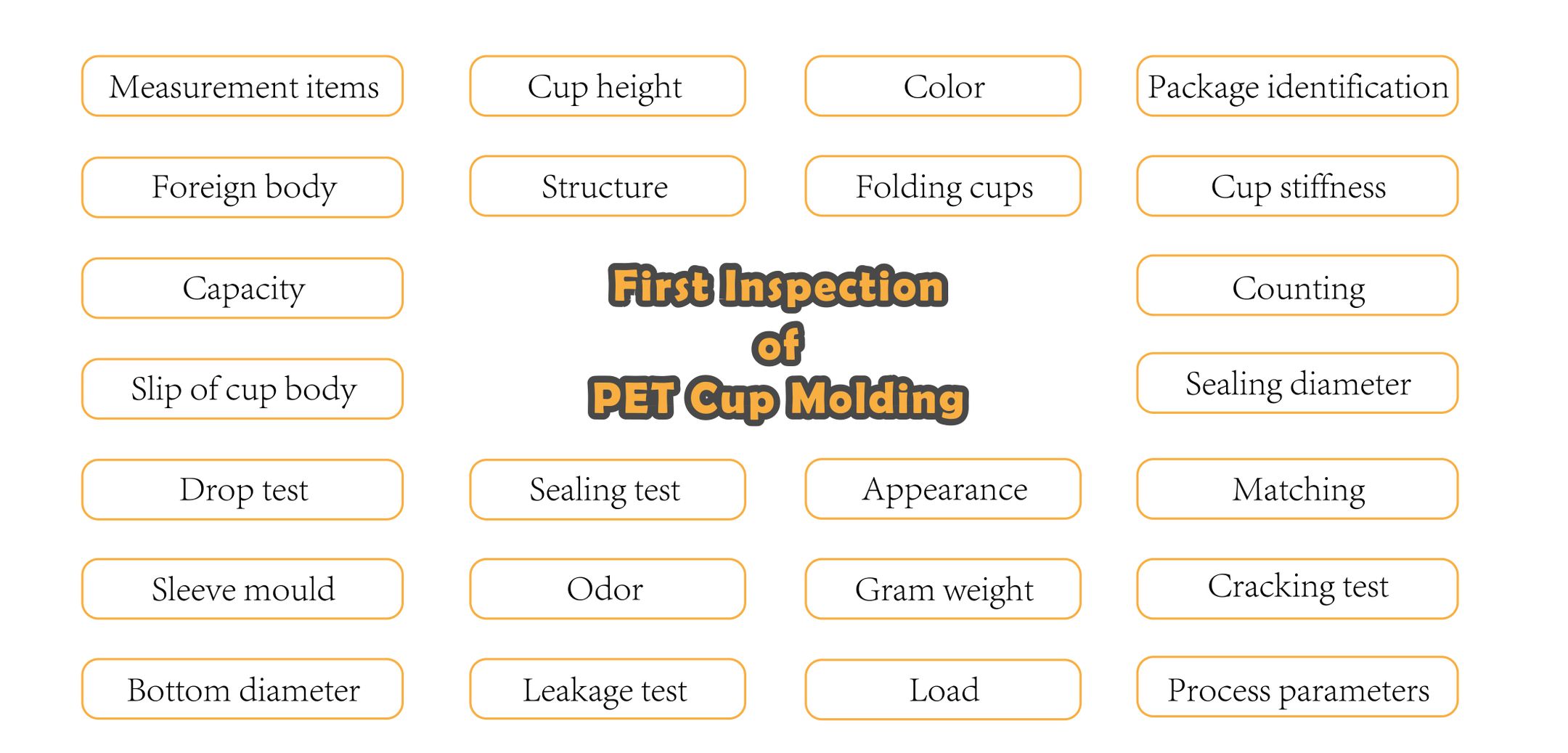

(Only the first inspection of molding during the manufacturing process requires 29 tests)

Strict quality control can ensure that product quality meets standards and meets consumers' needs and expectations; especially for food grade PET direct drinking containers, quality control can also help prevent potential safety problems in products and ensure the health and safety of consumers.

For us, quality control is not only a process and standard, but also an embodiment of JKai's values.